Watch this video to learn how to countersink a screw in metal properly and efficiently! Tech Team Expert Kurt Repsher walks you through the do's and don't's of countersinking a screw from planning to execution. Subscribe to our YouTube Channel to see more awesome unboxing, product feature and application videos like this one!

Why countersink A Screw?

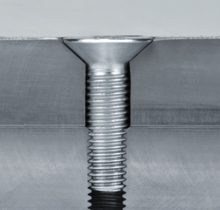

A countersink screw, like a flat head socket cap screw for example, has a taper that is largest at the head, with its size reducing gradually until it reaches the threaded shaft of the screw. Countersinking this type of screw in the metal allows the screw head to rest below the surface of the metal, utilizing the full structural strength of the screw and achieving a more professional finish. The countersink used to create the chamfer in the metal must match the size of the screw head, or you will jeopardize loss of the connection's structural integrity. Provided you pair the right countersink with the right screw, you'll achieve a tight fit and a recessed screw that does not obstruct the smooth surface of your workpiece.

Choosing the right countersink & screw

The most common chamfer angles are 82° and 90°, and while screws are available with varying head angles, they most commonly have an 82° angle. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° — each designed to match a particular screw’s head angle, with the most recognized in North America being the Unified Thread Standard of 82. Rule of thumb: always match your countersink angle and your screw head angle to ensure a tight fit and prevent loosening of the screw over time.

How To countersink a screw

Once you have determined the angle of your screw, select the corresponding countersink with that same angle. With the screw head's diameter, whether for countersinks or flat countersinks, you can determine the countersink's required diameter (again, this corresponds with the screw's measurements). Drill with the countersink up to the maximum diameter. For the flat countersink, you will also need to measure the height of the screw head to know how far into the workpiece you need to drill. Then, you can countersink your screw in the material flush with the surface.

Download & print your tap Drill Chart

Download and print the tap drill chart pdf for a quick reference table that will help you select the right tap and drill for your application, every time! Our comprehensive chart includes standard sizes, metric sizes, plug tap sizes and an 'at a glance' listing of the most popular tap drill sizes.