Installing a Quick Change Tool Post on your lathe can heighten your efficiency and allow for easier, faster set-up and tool changes. Watch as tech team member Kurt Repsher demonstrate how to select the right size tool post for your lathe and how to determine your machine's lathe swing.

Choosing the right quick change tool post for your lathe

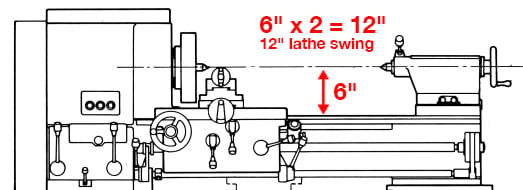

How To Determine your Lathe Swing

Lathe Swing, Swing Over Bed, or just Swing is the dimension representing the largest diameter workpiece that a lathe can rotate. This measurement does not include chuck jaws that might be holding the outside diameter of a workpiece. If this number is not provided on your lathe or in its manual, it can be determined by doubling the measured distance from the center of the spindle to the top of the closest way. For example, if you measure 6″, then you have a 12″ lathe swing. If you do not measure a whole number, be sure to round down in order to ensure you select the right size tool post. For example, if you measure 6.75" as the distance from the center of the spindle to the bed, when you double that measurement to 13.5", your lathe swing would equate to 13" as you'd round down to the nearest whole number.

Lathe Swing, Swing Over Bed, or just Swing is the dimension representing the largest diameter workpiece that a lathe can rotate. This measurement does not include chuck jaws that might be holding the outside diameter of a workpiece. If this number is not provided on your lathe or in its manual, it can be determined by doubling the measured distance from the center of the spindle to the top of the closest way. For example, if you measure 6″, then you have a 12″ lathe swing. If you do not measure a whole number, be sure to round down in order to ensure you select the right size tool post. For example, if you measure 6.75" as the distance from the center of the spindle to the bed, when you double that measurement to 13.5", your lathe swing would equate to 13" as you'd round down to the nearest whole number.

Once you've determined your machine's lathe swing, you can purchase a quick change tool post or quick change tool post set compatible with your lathe, referring to the manufacturer's specs to ensure you select a quick change tool post sized to work within your machine's lathe swing range.

Tech Tip:

Selecting the best size Quick Change Tool Post for your lathe:

The Lathe Swing is the primary determining factor in selecting the correct Tool Post. However, there are some lathes that will allow for either one of two Tool Post sizes.

- For example: On some lathe swing sizes, there might be an overlap in the Tool Post sizes, allowing for either one of two different size Tool Posts. Since each Tool Post size will only fit certain size tools and toolholders, get the Tool Post that will hold the tools you want to use with it.

- A larger size Tool Post will offer more versatility, while the smaller size is more economical.

- Using larger tools and toolholders can be advantageous because a broader variety of tools are available, and the larger tools will offer more strength and rigidity.

Note: The T-Slot Nut on any Quick Change Tool Post will need to be machined to fit the T-Slot on each individual lathe.

Need additional assistance selecting the right quick change tool post or tool post holder? Contact our tech team at tech@travers.com or submit a tech support request, here.

WAnt to learn about aluminum machining?

By downloading the Aluminum Machining Guide you'll find information on:

- Insert substrates, coatings & post treatment

- Troubleshooting insert failure

- Pros & cons of solid carbide vs. indexable tooling

- How to choose the right tool for your aluminum application

- Milling approach angles