Refractometers provide a quick, easy, and accurate way of testing and controlling coolant concentration. Watch Kurt Repsher demonstrate the correct way to use refractometers in our latest video.

How to use a refractometer

Prior to initiating any application with a refractometer, take the following steps to ensure optimal performance:

Prior to initiating any application with a refractometer, take the following steps to ensure optimal performance:

Focus YOur Refractometer

- Point the prism end of the refractometer toward a light source and focus the eyepiece until the scale is clearly visible and in focus. If you wear eyeglasses, remove them and focus the refractometer without them. Be sure the refractometer is creating a tight seal to your eye and allowing little to no light – this will help the visibility of the scale and make focusing easier. Refractometers feature an eye-guard to prevent stray light from entering the eyepiece and causing reflections.

- Once the lines of the scale are crisp and defined, your refractometer is in focus.

CalibratE YOUR Refractometer

- Calibrate the refractometer with a standard solution (typically included with the refractometer) before use. Since the reading will be adversely affected by changes in temperature, it is best to calibrate at room temperature, or within the test environment. If this is not possible, correction charts may be utilized. Some refractometers have automatic temperature correction (ATC), a feature that allows the instrument to automatically adjust and correct in account of temperature differences.

- Place a small amount of fluid, like 2–3 drops of distilled water for example, on the prism of the refractometer and carefully secure its cover plate. This will evenly distribute the liquid on the surface of the prism. Make sure there are no dry spots or air bubbles beneath the cover plate's surface.

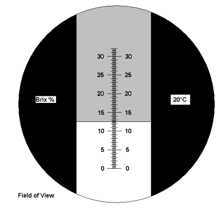

- Read the scale value at the intersection of the dark and light portions, at the point where they meet on the scale.

- Use a screwdriver to rotate the adjustment screw calibrate the refractometer, adjusting as needed until the light/dark boundary (shadow line) lines up with the zero line. After the zero adjustment, clean the prism with a soft cloth.

TEST your coolant

- Using a dropper, extract coolant from your machine.

- Again using the dropper, place 2–3 drops of coolant onto the prism of the refractometer and carefully secure its cover plate.

- Make sure there are no dry spots or air bubbles beneath the cover plate's surface.

- Read the scale value at the intersection of the dark and light portions, at the point where they meet on the scale. It may be necessary to adjust the position of the light source to maximize the contrast of the shadow line. Optimal contrast is usually be obtained by holding the instrument underneath and perpendicular to a light source.

- Once you have completed your testing, be sure to wipe the lens dry with a clean cloth (do not wash or rinse) and place the instrument in the supplied plastic case. Store the refractometer in a safe, dry environment.

What does your reading mean?

- Sharp line on the scale: the intersection of the dark and light portions of the scale will create a crisp, even line. Where that line falls on the scale equates to the concentration of your coolant.

- Fuzzy or uneven line on the scale: if the line created on the scale is not crisp and even, it's indicative of having tramp oil – way oil, hydraulic oil or spindle oil – present in your coolant. When tramp oils fall from a machine and into the sump, they form a floating seal that prevents air from reaching the coolant underneath. This creates an ideal setting for anaerobic bacteria that thrive in areas devoid of oxygen, leading to rancidity and coolant spoilage. To prevent rancidity and coolant separation, remove damaging tramp oil with a wheel skimmer. Remember that wheel skimmers can only be run when the coolant is not in use. Use the skimmer to clean your coolant and take another reading after you have done so to ensure concentration levels are optimal and the issue has been corrected.

WANT TO LEARN MORE?

Our Metalworking Fluids Guide includes critical information that can extend the life of your coolant and more.

Download the guide by clicking below. By downloading, you'll learn about:

Download the guide by clicking below. By downloading, you'll learn about:

- The functions of varying metalworking fluids

- Troubleshooting your metalworking fluids

- Optimal use of metalworking fluids in tapping applications

- Rustlick brand products selection guide

- ValCool brand products selection guide