As temperatures rise, so does the risk of heat stress that can lead to heat exhaustion, and in extreme cases, heat stroke. Proactively protecting your team on the shop floor, or your crew on a worksite, can reduce the threat of heat-related illness. Under OSHA law, employers are required to protect employees from known safety hazards, which include extreme heat conditions. Following OSHA guidelines and recommendations, recognizing the warning signs of heat-related illnesses, implementing a heat illness protection program, and making use of equipment including air circulators/fans, blowers, evaporative coolers, and moisture wicking and reflective clothing can reduce the risk of heat-related illness and increase the safety of your employees.

HEAT EXHAUSTION OR HEAT STROKE?

Knowing the symptoms and treatment of both heat exhaustion and heat stroke can literally be the difference between life and death. Training staff and making signage available for easy reference can prove critical during an emergency situation.

| HEAT EXHAUSTION SYMPTOMS: | HEAT STROKE SYMPTOMS: |

|

Feeling faint/dizzy |

Strong Headache |

|

Excessive sweating |

No sweat |

|

Cool, pale, clammy skin |

Red, hot, dry skin |

|

Rapid weak pulse |

Rapid strong pulse |

| Nausea/vomiting | Nausea/vomiting |

|

Muscle cramps |

Loss of consciousness |

|

HEAT EXHAUSTION TREATMENT: |

HEAT STROKE TREATMENT: |

|

Get to a cooler (preferably air-conditioned) place. |

Call 911 Take action to cool the person. Any delay can be fatal, so act immediately. |

KNOW THE REAL FEEL TEMPERATURE: HOW TO USE A HEAT INDEX CHART

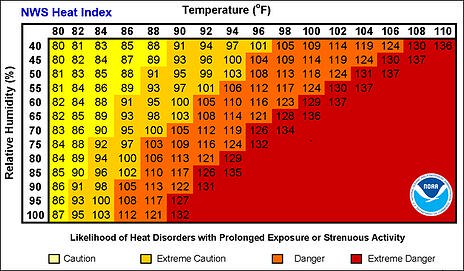

Locate the predicted high temperature across the top column (Air Temperature). On the left side locate the predicted humidity (Relative Humidity). Follow across and down to find the ‘Real Feel Temperature’. Note that the heat index chart most accurately represents mild conditions in the shade with light wind – exposure to full sun can increase values by up to 15°F. Strong winds, paired with hot, dry air are extremely hazardous. Generally, any day with a temperature of 80°F or higher requires additional caution, but the higher the temperature and relative humidity, the more elevated the risk of heat illness.

Download the NIOSH/OSHA Heat App [iOS | Android] to access a simple 'real feel temperature' heat calculator on your device.

PREVENTING HEAT ILLNESSES:

BEATING THE HEAT IN YOUR MACHINE SHOP:

In addition to the summer heat, machines constantly running can contribute to rising temperatures on your shop floor. Throughout the year, but especially during the summer, keeping your shop floor comfortable can be a challenge. When the heat index is high, using air circulators/fans and blowers to cool personal workstations and larger areas in your shop can lower the risk of heat related illness. In addition, investing in evaporative coolers to deliver cool, humidified air to hazardous areas where flammable gases or liquids are present is recommended.

In addition to making use of cooling equipment, the following is recommended:

- Be aware of elevated risk days when the heat index is high or when your shop and surrounding area are experiencing a heat wave (several consecutive days of high temperatures and humidity).

-

Plan for emergencies and train employees to recognize signs of heat stress and to watch out for symptoms (in themselves or each other).

-

Prevent dehydration and provide coolers with water or an electrolyte-rich sport drink. Encourage employees to drink at least (8) 8 ounce glasses/bottles a day.

-

Remember some applications, like welding, require heavy protective gear and use of equipment that radiates heat. On hot, elevated risk days, welders are especially vulnerable, and accommodating them with additional rest cycles (in a cool area) and ensuring they are well hydrated is especially important. When possible, schedule their work during cooler times of the day, like early morning or after sunset.

-

Design a place on the shop floor that keeps heat illness recovery items readily accessible (drinks, cold compresses, etc.)

BEATING THE HEAT AT YOUR OUTDOOR WORKSITE:

If your job site is outdoors, it is critical to be aware of elevated risk days when the heat index is high and your crew is most susceptible to heat illness. It is most important that you provide water, rest, and shade in regular intervals. Since standard electric cooling equipment is not optimal for outdoor use, wearing moisture wicking and reflective clothing that minimizes the skin’s absorption of heat, wearing sunscreen (SPF 30 or more), and staying hydrated is critical. The following is also recommended to implement or encourage at the job site:

- Prevent dehydration and provide coolers with water or an electrolyte-rich sport drink. Encourage employees to drink at least (8) 8 ounce glasses/bottles a day.

- If possible, reschedule outdoor shifts to the coolest times of the day, either early morning or after sunset.

- Plan for emergencies and train employees to recognize signs of heat stress and to watch out for symptoms (in themselves or each other).

- Wear lightweight, light-colored, loose-fitting clothing, and a wide-brimmed hat.

- Allow new or returning workers to gradually increase workloads and take more frequent

breaks as they acclimatize, or build a tolerance for working in the heat. - Design a place at the worksite that keeps heat illness recovery items readily accessible (drinks, cold compresses, etc.)

SUMMARY

Heat illnesses can affect anyone, regardless of age or physical condition. Under OSHA law, employers are responsible for providing workplaces that are free of known safety hazards, including extreme heat. An employer with workers exposed to high temperatures, whether within their shop or outdoors at a worksite, should mitigate aforementioned risk factors via OSHA recommendations. Taking steps to beat the heat increases the safety of your workplace, increases employee productivity and can save a life.

download your COMPREHENSIVE beat the heat guide

Best practices on protecting your team from heat related illness

Best practices on protecting your team from heat related illness- Printable heat related illness prevention posters in English & Spanish

- Details on how to read a heat index chart

- Helpful links & additional OSHA recommendations including heat stress planning