Your metalworking fluids serve as the lifeline of your shop, allowing for increased production, longer tool life, and more efficient chip removal. Use the information below to help pinpoint the cause of the most common metalworking fluid issues and potential ways to resolve them.

EXCESSIVE FOAMING:

Check the concentration: A mix that is too rich can contribute to foaming. Check concentration with a refractometer and adjust.

Mechanical problems: Check for a leak on the intake side or around the shaft seals of a coolant pump, which would result in air being drawn into the fluid, creating foam.

RUSTING OF PARTS:

The coolant mix is too lean: Check the concentration with a refractometer and adjust if necessary.

The pH is too low: Check pH with paper or a meter to ensure its above 7.5. If rust occurs, add 2% concentrate to sump and check the concentration again.

SHORT SUMP LIFE:

The concentration is too low: Check concentration with a refractometer and adjust if necessary.

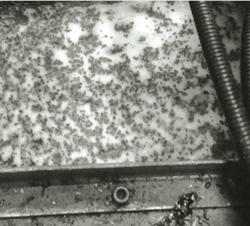

The tramp oil is sealing surface of sump: Take steps to reduce or remove floating tramp oils to prevent the rapid growth of anaerobic bacteria

HEAVY OR STICKY RESIDUES:

The coolant concentration is too rich: Check the concentration with a refractometer and adjust as necessary.

Excessive tramp oils contamination: Tramp oils can build up and coat machine surfaces. Use a skimmer to reduce or remove floating tramp oils.

Contact Travers Tool's expert technical advisors for assistance with proper metalworking fluid selection, additional troubleshooting tips, and more at tech@travers.com. Want to upload a photo of your metalworking fluids or sump, and get help pinpointing the cause of a current issue? Attach a photo and make a technical support request here.

Thanks for reading!

We believe the Right Tool Is Everything™, and we strive to share our experience and expertise in an effort to ensure you select the right tool for your application, follow best practices, and can push your productivity and efficiency further. Our Metalworking Fluids Guide includes critical information that can extend the life of your coolant and more.

Download the guide by clicking below. By downloading, you'll learn about:

-

The functions of varying metalworking fluids

-

Troubleshooting your metalworking fluids

-

Optimal use of metalworking fluids in tapping applications

-

Rustlick brand products selection guide

-

ValCool brand products selection guide