At Travers Tool, we know that precision machining depends on choosing the right tools for the job. One area that sometimes causes misunderstandings is when selecting a boring head. Customers often ask for the minimum and maximum boring capacities of a particular boring head.

The answer might be a little surprising: the capacity isn’t determined by the boring head itself, but rather by the boring bar used in it.

Boring Head Basics

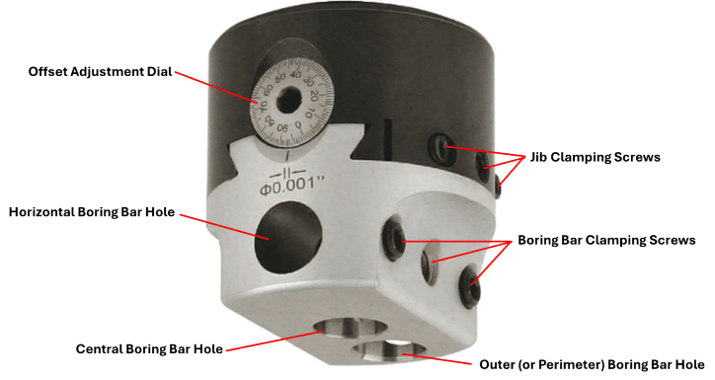

A boring head for mill is designed to hold boring bars and allow for fine, accurate adjustments. Adjusting the head moves the bar outward from center in controlled increments, giving you the ability to hit tight tolerances on hole diameters.

As a hypothetical example, I’ll use round numbers to simplify the explanation of a boring head’s minimum and maximum bore diameters.

For a broader overview of hole-enlargement methods, you can also refer to our guide on Reaming, Boring, and Trepanning.

Minimum Bore Diameter

- If a boring bar has a minimum bore diameter of 3/4", that’s the smallest hole the bar can start a bore in.

- When that boring bar is mounted in the central hole of a boring head, the head’s minimum bore diameter will also be 3/4", since the bar itself is the limiting factor.

If a boring head offers a maximum offset of 1", that means the bar can be adjusted to as much as one inch away from the centerline.

To find the maximum bore diameter with the bar in the central hole:

- Take half of the bar’s minimum diameter:

3/4" boring bar ÷ 2 = 3/8" - Add the head’s maximum offset:

3/8" + 1" = 1-3/8"

So, 1-3/8" is the largest bore diameter achievable from the central mounting position with that particular boring bar in it.

- If you mount the same bar in an outer (or perimeter) hole, simply add the distance between the centers of both boring bar holes and add that to the maximum bore diameter previously calculated (1-3/8") to determine the new, larger maximum diameter.

- Boring bars can also be mounted in the horizontal hole, allowing the bar to extend straight out the side of the head for even larger bores.

Whether it’s a boring bar that uses indexable inserts, or a solid boring bar , the boring bar is what ultimately determines the boring head’s capacities. Each bar has its own limitations in terms of:

- A small-diameter boring bar is effective for smaller bores, but it will only shallow depths.

- Longer boring bars can machine deeper holes, but since they are larger in diameter, the minimum bore size will also increase.

Choose a shank that matches the type of spindle of the machine you’ll be mounting the boring head on. This could be CAT40, Morse Taper, R8, or another style. You can also use a straight shank if you plan to run it in a collet or an end mill holder.

Most boring heads use either a 7/8"-20 or a 1-1/2"-18 female thread at the top. The shank you choose needs to have the matching male thread to fit properly.

TRAVERS TOOL TIP:

Most boring heads specify their adjustments in terms of radius movement. That means any adjustment you dial in will double when it comes to the actual diameter of the bore. For example, if you adjust the head by 0.010", the bore diameter will increase by 0.020". This happens because the cutting edge shifts outward from the centerline, effectively enlarging both sides of the hole.

To confirm how your boring head behaves, place an indicator against the adjustable slide of the head:

- If you dial in an adjustment and the indicator shows the same movement, your bore will increase by 2× that amount.

- If the indicator moves half of the adjustment you dial in, then the bore will grow by exactly the amount shown on the boring head’s scale.

- If your boring head has ø0.001” on it, like the one in the image, that means each line on the dial will make the diameter of the hole 0.002” larger.

A printable Decimal Equivalent Chart may help when interpreting fine adjustments.

At Travers Tool Co., we carry a wide range of boring heads, shanks, indexable boring bars, solid boring bars, complete sets, and related accessories from trusted brands. Whether you’re working on small, shallow precision bores or larger, deeper ones, we’ll help you pair the right boring head with the right shank and bars—so you get maximum accuracy and performance.