Watch this video to learn how to restore damaged threads on a screw or bolt in five easy steps! To view more exclusive application and product videos, subscribe to our channel!

Thread damage is a common and frustrating challenge that can occur as the result of a variety of factors. Typically, thread damage on a a male thread (a screw or a bolt for instance) is caused when incorrect bolt torque is used, when thread fretting occurs as a result of prolonged vibration during machining applications, or when the threads become worn after extended use over time. Damaged threads on a screw or bolt can often be fixed by running a die over it, and if a thread's damage is minimal, it may be possible to reform the threads by running a nut up and down them, though that runs the risk of the nut fusing to the thread (galling).

We recommend following the steps illustrated in the video and below to ascertain the screw's or bolt's threads per inch (T.P.I) with a thread pitch gage (like the Starrett Thread Pitch Gage No. 472) and repair the damaged threads by making use of external thread restoring files.

restoring threads on your screws & bolts In 5 easy steps

- Ascertain the screw's or the bolt's threads per inch (TPI) with a thread pitch gage. The gage edge will fit perfectly into the remaining threads when you have the correct gage blade selected (there will be no gaps between the gage's teeth and the edge of the screw's or bolt's remaining threads). See below, and notice the gage's teeth fall perfectly within the threads… the correct TPI in this illustration, is 10.

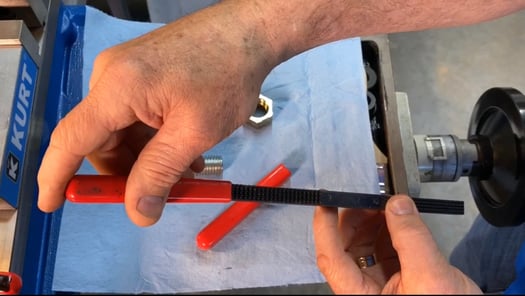

- Find the appropriate TPI pitch on the thread file (10 TPI in this example).

- Install the handle on the opposite end and side from the correct pitch

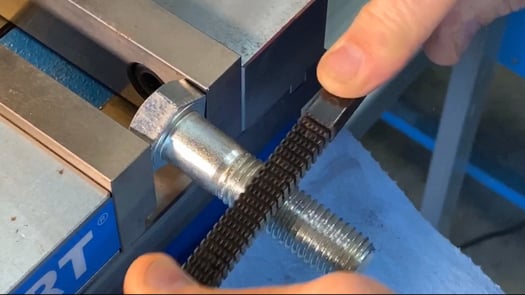

- Mount the damaged screw or bolt in a vise or chuck so it remains secure.

- With the correct pitch facing towards the screw, file at the same angle as the threads.

Want to learn more about thread repair methods & thread repair kits? Click here!