Mounting a Vise on a milling machine involves careful cleaning and preparation to ensure precision. Here’s a quick overview of the process: -

Safety First

- Remove any cutting tools to avoid accidents during the process.

- Remove jewelry like watches, necklaces, rings, etc. to prevent snagging.

- Always Wear Safety Glasses. Your eyes should be well protected when using compressed air or sprays. If you wear prescription glasses like I do, consider OTMT Safety Glasses that will fit over them.

Prepare the Table

- Clean off chips and debris: Thoroughly clean the milling machine table and T-Slot using a T-Slot Cleaner, Brush, and a Vaccuum

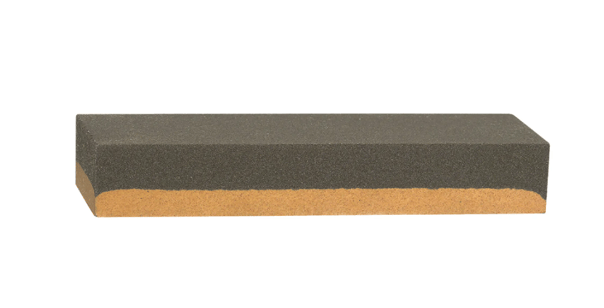

- Stone the surface: Lightly stone the table with 320-grit (or finer) Flat stone and light oil to remove burrs or irregularities. Stoning the table ensures the vise sits flat and helps prevent your hand from catching on a burr.

- Final check: Run your clean hand over the surface to ensure that it’s smooth and clean.

Prepare the Machine Vise

- Clean the vise: Brush off chips, use a Vacuum or compressed air, then wipe with a cleaner to remove any residue using Clean Shop Rags.

- Stone the bottom of the vise: Lightly stone the base of the vise to remove burrs, just like you did with the table.

- Final hand check: Run your hand over the vise base to ensure that it's smooth and clean.

Mount the Vise

- Apply rust inhibitor: Spray a bit of Rust Inhibitor on the table and vise base to protect against corrosion.

- Position the vise: Carefully slide the vise around on the table before securing it into place. If you missed some swarf on the table, or if something fell out of the bottom of the vise, sliding it around will push the debris to the side of the vise, rather than remaining underneath it.

- Secure the vise: Tighten the vise using Flange nuts, Flat Washers and T-Slot Bolts to secure the vise in place.

With these steps, you’ll have a properly mounted machine vise for precise milling operations!

Essential Tools and Products for Mounting a Vise

To ensure a successful and precise vise mounting process on your milling machine, here are the essential tools and products you'll need:

- Safety Glasses: Protect your eyes during cleaning and mounting.

- Vacuums: Keep your workspace free from debris and chips.

- T-Slot Cleaners: Efficiently clean the T-slots of your milling machine.

- Dustpan Brushes: Remove fine dust and chips from surfaces.

- Chip Brushes: Ideal for clearing away larger chips and debris.

- Dead Blow Mallet: Gently secure your vise without damaging it.

- Rust Inhibitor: Protect metal surfaces from corrosion.

- Shop Rags: Keep your workspace clean and tidy.

- Sharpening Stone: Smooth surfaces and remove burrs for better contact.

- Machine Vises: The main component for holding your workpieces.

- Vise Speed Handle: For quick and easy adjustments to your vise.

- Indicator Spindle Mounts: Ensure precise alignment of your workpiece.

- Magnetic Indicator Holder: To securely mount an indicator to a machine's table, or another magnetic surface.

- Vise T-Slot Keys: Secure the vise for optimal stability

- T-Slot Bolts: Essential for mounting your vise securely.

- Flange Nuts: Provide a secure fastening for your T-slot bolts.

- Flat Washers: Ensure an even load distribution when fastening.