A machine taper secures tool holders or cutting tools in the spindle. A conical-shaped tapered shank fits into the same MT size female socket. Watch this video and learn how to determine the size of your machine's Morse Taper, the most popular style taper found on most machinery. Subscribe to our YouTube Channel to check out more 'how to' videos like this one.

What Is A Morse Taper?

A Morse Taper (abbreviated MT) is a tapered spindle or shank usually found on lathes, drill presses and other industrial machinery to mount tool holders or tooling including centers, collet chucks, collets and drill chucks. Morse Tapers on the headstock of your lathe have a hollow housing that is designed to fit a male ended arbor.

What tools do i need to measure my morse taper?

A Morse Taper's large diameter, small diameter, or length can most easily be measured using a dial caliper or digital caliper. To watch a video on how to read a dial caliper, click here. Taper length can also be measured with a tape measure. To measure your Morse Taper's Taper Per Inch (Taper/Inch), you can utilize a caliper (a digital caliper recommended with this method) and 1-2-3 blocks on any flat, smooth surface. Once you've placed your Morse Taper's shank between 1-2-3 blocks that are in the 1" position (while on a flat, smooth surface as demonstrated in the video), with the caliper jaws placed firmly down upon the 1-2-3 block surface and closed in against the taper, zero your caliper. Change the position of your 1-2-3 blocks from the 1" to the 2" position and measure the taper (again, with your caliper's jaws placed firmly against the 1-2-3 blocks) and capture the taper's shank dimensions in this position. Refer to the chart's Taper/Inch column and find the closest Taper Per Inch measurement to the measurement you just captured. To learn more ways to use 1-2-3 blocks, watch our How To Use 1-2-3 Blocks video, here.

How do I determine the size of my morse taper?

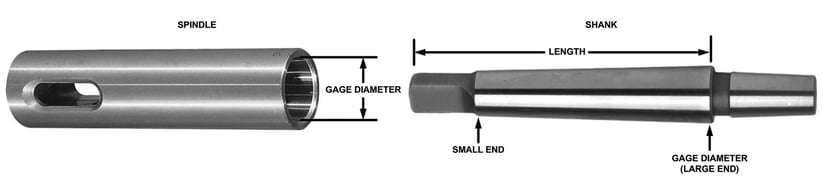

When determining the Morse Taper (MT) size of your machine's headstock (if it has an MT), tailstock or spindle, you have a few options. You can measure the shank diameter of an existing center you may have that fits. If you don't have an existing center or drive to measure, you can measure the opening of the Morse Taper spindle. Most lathes use one size Morse Taper in the headstock and another size Morse Taper for the tailstock, so be diligent and check both in order to determine the right Morse Taper size and corresponding accessories for your lathe. Because of the tapering of the shank, the shank's diameter measurement will vary when using calipers depending on where you measure along the shank.

Option 1: Measure An Existing Center That Fits

Already have a center or accessory that fits your machine and want to be sure you're ordering the correct Morse Taper size? Simply measure measure either the large diameter, the small diameter, or the length of the Morse Taper to find the corresponding MT size using the chart below.

Option 2: Measure the diameter of your spindle's openinG

Use a caliper to measure the inside diameter of the opening of the Morse Taper hollow socket (the opening) in your spindle and find the corresponding MT size using the chart below.

NOTE: You just need to measure one dimension from the chart below to be able to determine your machine's Morse Taper size. While measuring the large end diameter of the taper is the most common practice, you can measure the small end diameter or length if preferred. Your measurements may not be 'exact' but should be close enough to a dimension to make the correct taper size evident. For instance, if the large end diameter reading is .698", round 'up' to .700" and identify the taper as a size #2 .

Morse Taper Dimension Chart

Please scroll to end of this blog for a link to a free downloadable, easy to print, Taper Dimension PDF chart, complete with the most popular tapers and their dimensions. See directly below for morse taper dimensions.

Refer to the taper dimensional guide below to determine your machine's morse taper size:

| Taper | Large End Dia. | Small End Dia. | Length | Taper/Inch | Angle From Center |

| #0 | 0.356" | 0.252" | 2.00" | .0521 | 1.4908° |

| #1 | 0.475" | 0.369" | 2.13" | .0499 | 1.4287° |

| #2 | 0.700" | 0.572" | 2.56" | .0500 | 1.4307° |

| #3 | 0.938" | 0.778" | 3.19" | .0502 | 1.4377° |

| #4 | 1.231" | 1.020" | 4.06" | .0519 | 1.4876° |

| #4-1/2 | 1.500" | 1.266" | 4.50" | .0520 | 1.4894° |

| #5 | 1.748" | 1.475" | 5.19" | .0526 | 1.5073° |

| #6 | 2.494" | 2.116" | 7.25" | .0521 | 1.4933° |

| #7 | 3.270" | 2.750" | 10.00" | .0520 | 1.4894° |

Do you have more questions about how to determine your machines's taper? Contact our tech team at 800.234.9985, email tech@travers.com, or submit an online tech support request here.

Download & print your free taper dimension chart

Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! Our comprehensive chart includes 'at a glance' listing of the most popular taper styles including BT Shank, CAT Shank, Jacobs Taper, Morse Taper, NMTB Shank and R8 Shank.