NIKCOLE GCS-5 ON-EDGE GROOVING & PARTING SET

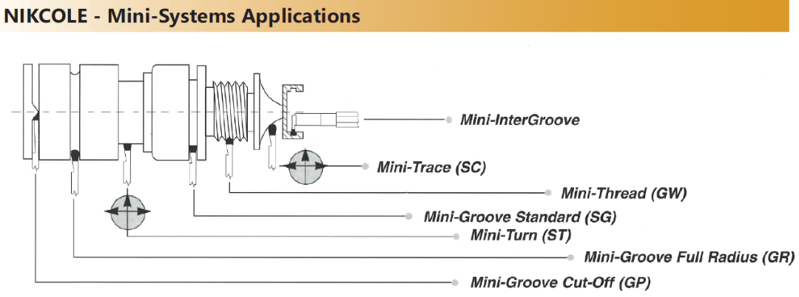

The NIKCOLE Mini-Systems are a family of compact, high-precision cutting tools designed specifically for narrow grooving, cut-off, threading, profiling, and related operations—especially in confined spaces or on small-diameter parts.

System Philosophy and Design Highlights

- The NIKCOLE Mini-System is built on a modular concept: a small number of tool holders paired with a broad palette of interchangeable inserts.

- Each holder uses a single positive-locking insert screw (Torx Plus style) to clamp the insert, simplifying setup and reducing hardware complexity.

- The insert pockets are precision-machined to ensure repeatable cutting-edge location, promoting consistent performance across multiple insert changes. For even greater setup accuracy and repeatable tool heights, explore our guide on Edge Technology Lathe Tool Height Gages.

- Inserts are produced to tight tolerances; for example, in the GCS-5 set, insert width tolerance is +0.0009″ / –0.0000″ (±0.02 mm).

- All components are manufactured in the USA under ISO 9001–level quality controls.

Because of this design, one holder can support multiple operations (grooving, parting, facing, profiling, even threading), offering cost-effectiveness versus a large array of dedicated tools.

Capabilities and Performance Range

The NIKCOLE Mini-System supports:

- Grooving / slotting / narrow grooves with insert widths down to 0.020″ (0.5 mm).

- Cut-off / parting operations for external work, especially in tight-access applications.

- Turning, profiling, copying on small parts, especially where conventional tool geometry would be obstructed.

- Internal grooving, threading, and profiling via compatible boring bar adapters.

- Threading (external or internal) in pitches from 40 to 13 TPI (or 0.7 mm to 1.75 mm) using specialized GW (threading) inserts.

Because each insert offers two cutting edges, tool life is extended before reindexing or replacement.

The system is especially well-suited for applications such as:

- Micro-grooves or slots in molds or small shafts

- Precision profiling of miniature parts

- Fine internal grooving or threading where diameter constraints limit tooling clearance

- Jobs requiring frequent insert changes, minimal downtime, and consistent location repeatability

NIKCOLE GCS-5 On-Edge Grooving & Cut-Off Set (Item #55-542-350)

This 7-piece kit is among the most popular NIKCOLE starter sets.

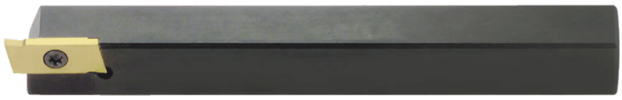

- Holder: THE-7-1/2 R, a right-hand external toolholder with a 1/2″ square shank

- Five carbide inserts, Grade C6-PV (PVD / TiAlN + TiN coated),

in cutting widths of 0.035″, 0.043″, 0.051″, 0.063″, 0.073″ - One Torx locking screw (spare)

- One Torx wrench

- Fitted protective case

Key Advantages:

- Because all inserts in the kit are interchangeable (same pocket design), you can switch thickness or geometry without changing the holder.

- The compact, repeatable nature of the system reduces setup and downtime.

- Quality assurance and tolerances built into the system deliver consistent edge location and performance across insert swaps.

In sum, the GCS-5 set acts as a versatile “go-to” toolkit for small-scale grooving, turning, facing, profiling, and threading tasks where precision and flexibility are critical.

Other Available Toolholders (External & Internal)

To support a wider range of part diameters and geometries, NIKCOLE offers an assortment of holders and bars:TURNING / EXTERNAL TOOLHOLDERS

- The turning/external toolholders are designed for external grooving, cutoff, threading, turning, facing, profiling, and copying.

- Each toolholder will work with all inserts of the correct hand-direction.

- Square-shank Monoblock Turning Toolholders are available in both left-handed or right-handed and in inch or metric sizes (3/8", 1/2", 5/8", 8 mm, 10 mm, 16 mm).

- Use right-hand inserts in right-hand Toolholders, and left-hand inserts in left-hand Toolholders.

- Inserts are not included with individual Toolholders.

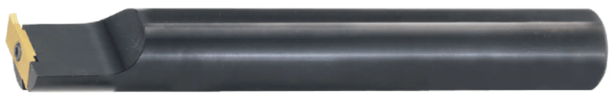

BORING BARS / INTERNAL HOLDERS

- The boring bars/ internal holders are designed for internal grooving, threading, turning, profiling, and copying.

- Each Boring Bar will work with all inserts of the correct hand-direction.

- Round-shank internal Boring Bars are available in both left-handed or right-handed and in inch or metric sizes (3/4", 1", 1-1/4", 20 mm, 25 mm, 32 mm).

- Use left-hand inserts in right-hand Boring Bars, and right-hand inserts in left-hand Boring Bars.

- Inserts are not included with individual Boring Bars.

For additional product information, explore the NIKCOLE section in our Master Catalog and Essentials Catalog.

REPLACEMENT SCREW & WRENCH

| Product | Image |

|---|---|

| NIKCOLE - 72556-IP8, M3X8.0 Torx Plus Screw | |

| Torx Plus IP8 Wrench |  |

NICKOLE MINI SYSTEMS INSERTS

GP – GROOVING & PARTING INSERTS

- Grooving & Parting Inserts include three carbide grades:

- C2: Recommended for non-ferrous, cast iron, exotic alloys, hard materials.

- C5-PV: PVD / TiAlN + TiN coated grade recommended for machining steels and stainless steels, cutting solid bars to the center and for interrupted cuts.

- C6-PV: PVD / TiAlN + TiN coated grade recommended for machining steels and stainless steels, parting and grooving at higher speeds.

- 7° left-hand or right-hand lead angles, or neutral.

- Available widths: .039”, .059”, .078”

SC – STANDARD GROOVING & PARTING INSERTS

- Standard Grooving & Parting Inserts include three carbide grades:

- C2: Recommended for non-ferrous, cast iron, exotic alloys, hard materials.

- C5-PV: PVD / TiAlN + TiN coated grade recommended for machining steels and stainless steels, cutting solid bars to the center and for interrupted cuts.

- C6-PV: PVD / TiAlN + TiN coated grade recommended for machining steels and stainless steels, parting and grooving at higher speeds.

- Available widths: .019”, .027”, .031”, .035”, .043”, .051”, .063”, .073

GR – FULL RADIUS GROOVING INSERTS

- Full Radius Grooving Inserts include three carbide grades:

- C2: Recommended for non-ferrous, cast iron, exotic alloys, hard materials.

- C5-PV: PVD / TiAlN + TiN coated grade recommended for machining steels and stainless steels, and for interrupted cuts.

- C6-PV: PVD / TiAlN + TiN coated grade recommended for machining steels and stainless steels, and grooving at higher speeds.

- Available widths: .039”, .059”, .078”, each with a full radius.

SC – COPYING/PROFILING INSERTS

- Copying/Profiling Inserts include two carbide grades:

- C2: Recommended for non-ferrous, cast iron, exotic alloys, hard materials.

- C5-PV: PVD / TiAlN + TiN coated grade recommended for machining steels and stainless steels, and for interrupted cuts.

- Width: .125”, with a full .0625” radius.

- Depth of Cut: .235”

GW – THREADING INSERTS

- Thread pitch range is from 40 to 13 TPI (0.7 mm to 1.75 mm).

- Pitch Types: 60° for metric and standard threads, and 55° for British threads.

- Threading Inserts include three carbide grades:

- C2: Recommended for non-ferrous, cast iron, exotic alloys, hard materials.

- C5-PV: PVD / TiAlN + TiN coated grade recommended for threading steels and stainless steels.

- C6-PV: PVD / TiAlN + TiN coated grade recommended for threading steels and stainless steels at higher speeds.

To get the most from your NIKCOLE Mini tools, keep the following in mind:

- Stable setup is critical. Because groove widths are small, vibration control and rigid fixturing help avoid chatter and edge wear.

- Use light depths of cut when first dialing in. Especially when running very thin inserts (0.020″–0.035″), start conservatively.

- Use correct grade selection:

- C2 for non-ferrous, cast iron, exotic, or hard materials.

- C5-PV for steel, stainless, and interrupted cuts.

- C6-PV for higher-speed steel/stainless applications or more aggressive cutting.

- Insert indexing matters. Tracking insert orientation and using both edges helps even wear.

- Cooling / chip control: Ensure adequate flood coolant where possible to evacuate chips from narrow grooves.

- Consistent insert seating: Be sure the insert sits flush in the pocket with the locking screw torqued to spec to maintain repeatable edge location.

Why Choose NIKCOLE FROM Travers Tool Co.?

At Travers Tool, we recognize that many shops struggle with tooling for tight, precision grooving or cut-off tasks. The NIKCOLE Mini-System addresses this head-on:

- Minimal holders, maximal flexibility

- High repeatability of edge location

- Ultra-narrow groove capability

- Full system support (external, internal, threading)

- U.S.-based manufacture, quality controls, and distribution support

If your work involves micro-grooves, cut-off in constrained areas, internal grooving or threading, or you want to reduce tool change complexity, the NIKCOLE Mini-System is a strong candidate. Contact your Travers Tool representative for availability, pricing, or application recommendations.

Looking to optimize your turning setup further? Don’t miss our detailed guide on Quick-Change Tool Posts and How to Choose the Right Size for Your Lathe.